Information sheet

In the context of this cooperation, the profiles for setup of the gypsum plasterboard systems of galvanized steel with thickness of 0.55 mm made in Romania, Estonia and Ukraine are produced. The quality of the manufactured products complies with the international standards that allow using such products for installation of the gypsum plasterboard structures of any complexity. Use of the profile with the steel thickness of 0.55 mm in the construction industry allows increasing the load-bearing capacity of the wall frames by 30 %; of the suspended ceiling frames – by 78 % (as compared with the profile with thickness of 0.4 – 0.45 mm).

These products are certified (Certificate of Conformity UA1.058.0020895-11, the Certificate validity period: 24 of February 2011 – 23 of February 2013, and it complies with GOST 14918-80, par. 1.1, 1.3, 3.2, 3.4-3.10, GOST 11474-76, par. 1.1, 2.1-2.4, 2.6.). No expiry date. Guaranteed storage life – 1 year after manufacture date.

As the most metals are exposed to aggressive destructive effect of ambient air, only zinc-plated metal gypsum plasterboard profiles are produced. In the air, the zinc carbonate layer protecting from oxidation is formed on zinc. The zinc coating is firmly coupled to the metal surface and forms the effective protective layer, which can be damaged only by strong acid attack. The cutting lines of the zinc-plated profiles do not need additional corrosion protection. The profile geometric dimensions comply with the KNAUF system.

Depending on application, the gypsum plasterboard profiles may be:

- main or guiding ones;

- wall or ceiling ones.

The main gypsum plasterboard profiles are designed for heavy loads and are a base for fastening of the gypsum plasterboards. They differ in appearance or more specifically in C-shaped curved edges and ribbed stiffeners. The main profiles for gypsum plasterboards are divided into wall profiles or studs (CW) and ceiling profiles (CD).

The guiding gypsum plasterboard profiles are used as the horizontal channels, into which the main vertical profiles are inserted, or as a base for fastening of the boards. These profiles are U-shaped. The guiding gypsum plasterboard profiles are also divided into wall (UW) and ceiling (UD) ones. There are ribbed stiffeners on the profile walls, which improve the profile stiffness.

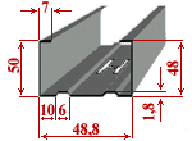

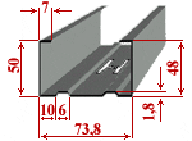

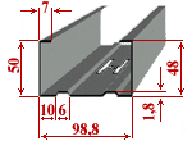

Plasterboard CW stud

CW stud is a main element for setup of the frame of the light partition walls, to which the gypsum plasterboards are fastened. CW profile is made by cold rolling of galvanized steel band with thickness of 0.55 mm. CW stud nominal size shall be selected based on the required height and structure of the gypsum plasterboard partition and sound insulation requirements.

CW studs are C-shaped and serve as the main vertical studs of the gypsum plasterboard structure frames. CW stud is installed together with the size matching UW channel.

The leg with width of 50 mm is greatly improves the screwing foreman work during fastening the gypsum plasterboards as it is unlikely that the screw misses the profile leg. The plasterboards must be installed on the CW profile leg. There are two H-shaped ports on the profile ends, which allow installation of the utility lines inside the partitions and claddings. There are longitudinal grooves improving the profile stiffness on the CW profile wall.

The notches on the profile legs, which center the bolt screw when screwing it in, are also the advantage of CW profile. The stud is fastened in the channel by using the notch type sealer or self-drilling screws.

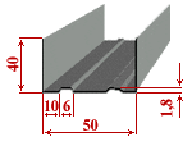

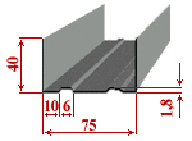

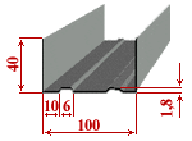

Gypsum plasterboard UW channel

UW channel is made by cold rolling of galvanized steel band with thickness of 0.55 mm.

UW channels are U-shaped and serve as guides for CW studs and for set up of the crossbars between them in the partition and cladding frames. They are installed together with the size matching CW stud.

UW channel nominal size shall be selected based on the required height and structure of the gypsum plasterboard partition and sound insulation requirements. The leg with width of 40 mm greatly improves the screwing the fastening bolt screws during installation of the gypsum plasterboard structure.

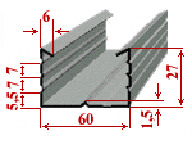

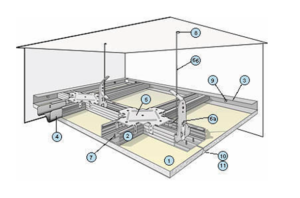

Ceiling gypsum plasterboard CD profile

The ceiling CD profile is made by cold rolling of galvanized steel band with thickness of 0.55 mm.

The ceiling CD profiles are C-shaped and designed for making the frame of the suspended ceilings and wall cladding. They are installed together with the size matching UD channel.

The CD profile legs are provided with three grooves, which increase their stiffness.

The ceiling CD profile is fastened to the load-bearing base by using the special hangers, among which the direct hanger and the rotating hanger with clamp are the main ones. For installation of the rotating hanger with clamp, the CD profile leg edges are incurved and serve as a stop. The notches on the profile wall, which center the bolt screw when screwing it in, are also the advantage of CD profile. The central wall groove is a reference point both during accurate frame assembling and gypsum plasterboards installation. The wide wall of a profile is a usable base for fastening of the gypsum plasterboards.

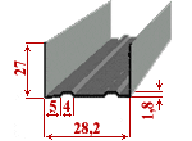

Gypsum plasterboard UD channel

UD channel is made by cold rolling of galvanized metal band with thickness of 0.55 mm.

UD profiles are U-shaped and serve as the guides for CD profiles when making the frame of the suspended ceilings and wall cladding. They are installed together with the size matching CD profile. During installation of the suspended ceiling, UD profile is fastened to the walls along the perimeter of the premise. In case of cladding, the profile is fastened to the ceiling and floor.

UD profile is fastened to the load-bearing base with the expansion dowels.

There are longitudinal grooves improving the profile stiffness on the UD profile wall. There are 6 mm ports at a pitch of ~450 mm for fastening the profile to the load-bearing base with the expansion dowels.

Gypsum plasterboard UD channel

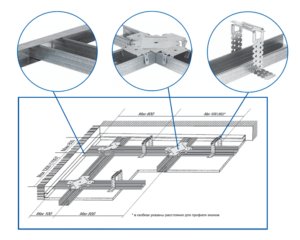

Stud-to-channel connection

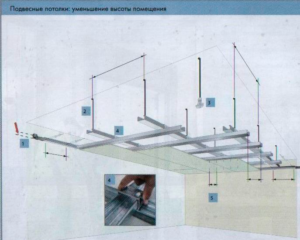

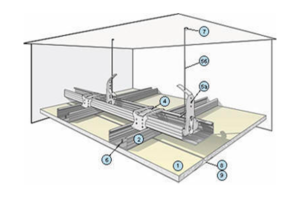

CEILINGS

Gypsum plasterboard ceiling on a single-level frame.

| Name | Unit | Usage rate per 1 m2 |

| 1. Gypsum plasterboard (MRGPB) | m2 | 1,05 |

| 2. Ceiling stud CD 60/27 | rm | 2.9 |

| 3. Channel UD 28/27 | rm | perimeter |

| 4. Longitudinal connector for CD 60/27 | pcs. | 0.2 |

| 5. Single-level profile connector (cross-connector) | pcs. | 1.7 |

| 6a. Hanger with clamp | pcs. | 0.7 |

| 6b. Ring bar for hanger with clamp | pcs.. | 0.7 |

| 7. Self-drilling screw ТN25 | pcs. | 23 |

| 8. Ceiling expansion dowel (anchor Bierbach) | pcs. | 0.7 |

| 9. Expansion dowel “K” 6/40 | pcs. | perimeter*2 |

| 10. Reinforcing tape | m | 1.2 |

| 11. Start putty | kg | 0.35 |

| Board surface putty | kg | 1.2 |

| Primer | l | 0.1 |

| 5c. All-purpose hanger 125/60 for CD 60/27 | pcs. | 0,7 |

| 5d. Self-drilling screw LN 9 | pcs. | 1,4 |

| * When the suspended ceiling is lowered by maximum 125 mm from the base floor slab |

Gypsum plasterboard ceiling on a two-level frame.

| Name | Unit | Usage rate per 1 m2 |

| 1. Gypsum plasterboard (MRGPB) | m2 | 1,05 |

| 2. Ceiling stud CD 60/27 | rm | 3.2 |

| 3. Longitudinal connector for CD 60/27 | pcs. | 0.6 |

| 4. Two-level profile connector 60/60 | pcs. | 2.3 |

| 5a. Hanger with clamp | pcs. | 1.3 |

| 5b. Ring bar for hanger with clamp | pcs. | 1.3 |

| 6. Self-drilling screw ТN25 | pcs. | 17 |

| 7. Ceiling expansion dowel (anchor Bierbach) | pcs. | 1.3 |

| 8. Reinforcing tape | m | 1.2 |

| 9. Start putty | kg | 0.35 |

| Board surface putty | kg | 1.2 |

| Primer | l | 0.1 |

| 5c. All-purpose hanger 125/60 for CD 60/27 | pcs. | 1.3 |

| 5d. Self-drilling screw LN 9 | pcs. | 2.6 |

| * When the suspended ceiling is lowered by maximum 125 mm from the base floor slab |

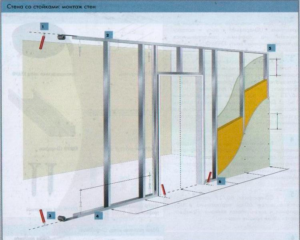

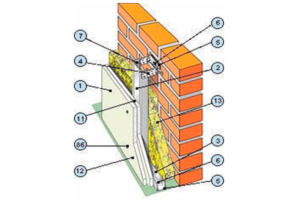

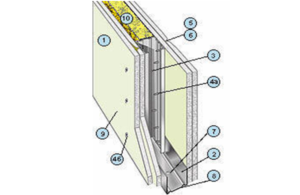

Wall constructions

| Name | Unit | Usage rate per 1 m2 |

| 1. Gypsum plasterboard – GPB | m2 | 1,05 |

| 2. Ceiling stud CD 60/27 | rm | 2 |

| 3. Channel UD 28/27 | rm | 0.8 |

| 4. Marvel at the straight lines 60/27 (Detail ES) | pcs. | 1.32 |

| 5. Sealing tape | m | 0,85 |

| 6. Expansion dowel “K” 6/40 | pcs. | 2,2 |

| 7. Self-drilling screw LN 9 | pcs. | 2,7 |

| 8а. Self-drilling screw TN 25 | pcs. | 17 |

| 10 . Longitudinal connector for CD 60/27 | pcs. | 0,2 |

| 11. Reinforcing tape | m | 1,1 |

| 12. Putty | kg | 0,3 |

| 13. All-purpose deep primer | l | 0,1 |

| 14. Mineral wool slab | m2 | 1 |

| 15. Finish board surface putty | kg | 1.2 |

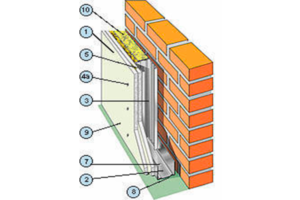

| Name | Unit | Usage rate per 1 m2 |

| 1. Gypsum plasterboard – GPB | sq.m | 1,05 |

| 2. ChannelUW 75/40 ( 100/40) | rm | 1.1 |

| 3. Stud CW 75/50 ( 100/50) | rm | 2 |

| 4. Self-drilling screw TN 25 | pcs. | 17 |

| 5. Putty | kg. | 0,45 |

| 6. Reinforcing tape | rm | 1,1 |

| 7. Expansion dowel “K” 6/40 | pcs. | 1.6 |

| 8. Sealing tape | rm | 1.2 |

| 9. All-purpose deep primer | l | 0,1 |

| 10. Mineral wool slab | sq.m | 1 |

| 11. Finish board surface putty | kg. | 1.2 |

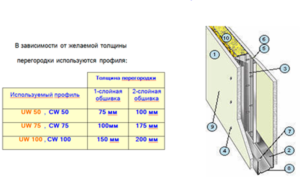

PARTITIONS

Gypsum plasterboard partition with one-layer siding on metal frame.

| Name | Unit | Usage rate per 1 m2 |

| 1. Gypsum plasterboard – GPB(MRGPB) | sq.m | 2.1 |

| 2. Channel UW 50/40 (75/40, 100/40) | rm | 0.7 |

| 3. Stud CW 50/50 (75/50, 100/50) | rm | 2 |

| 4. Self-drilling screw TN25 | pcs | 34 |

| 5. Start putty | kg | 0.9 |

| 6. Reinforcing tape | rm | 2,2 |

| 7. Expansion dowel “K” 6/40 | pcs | 1.5 |

| 8. Sealing tape | rm | 1.2 |

| 9. All-purpose deep primer | l | 0,2 |

| 10. Mineral wool slab | sq.m | 1 |

| 11. Finish board surface putty | kg | 1.2 |

| 12. Corner profile | rm | as required |

Gypsum plasterboard partition with two-layer siding on metal frame.

| Name | Unit | Usage rate per 1 m2 |

| 1. Gypsum plasterboard GPB(MRGPB | sq.m | 4,05 |

| 2. Channel UW 50/40 (75/40, 100/40) | rm | 0.7 |

| 3. Stud CW 50/50 (75/50, 100/50) | rm | 2 |

| 4а. Self-drilling screw TN25 | pcs. | 14 |

| 4б. Self-drilling screw TN 35 | pcs. | 30 |

| 5. Putty | kg | 1,5 |

| 6. Reinforcing tape | rm | 2.2 |

| 7. Expansion dowel “K” 6/40 | pcs. | 1.5 |

| 8. Sealing tape | rm | 1,2 |

| 9. All-purpose deep primer | l | 0.2 |

| 10. Mineral wool slab | sq.m | 1 |

| 11. Board surface putty | kg | 1.2 |

| 12. Corner profile | rm | as required |